Critical Evaluation of Toyota Corporation: Recall of Hybrid Vehicles 2014-2015 and 2016-2017

Critical Evaluation of Toyota Corporation: Recall of Hybrid Vehicles 2014-2015 and 2016-2017

Introduction

This report critically evaluates within the context of the problem-solving and decision-making techniques the major problem experienced by Toyota Motor Corporation and further discusses the other appropriate techniques for solving this problem. The report also analyses Toyota’s trend analysis of share prices at the time the problem occurred. It further evaluates the views and responses of investors to this particular problem and how Toyota company’s response.

Brief Company Background

Toyota Motor Company is a Japanese based Automaker Company recognized globally as the market leader in the automobile industry. It was founded in Japan in 1937 by Sakish Toyoda. It is headquartered in Toyota City with several manufacturing distributed throughout the world. Its primary business segment are manufacturing, automotive-design, sales, robotics, and financial segments. Initially, Toyota Motor Corporation focused on producing small-sized cars. Following its focus on improving innovation and technology, including a uniquely designed management philosophy, Toyota Motor Company started manufacturing medium to large-sized cars with hybrid and conventional engines. This expanded its product line-up to include compact and subcompact cars, mid-size luxury specialty and sports cars, mini-vehicles, sport-utility and recreational vehicles, minivans, pickup trucks, buses and trucks. The latest hybrid models produced by Toyota Motor Corporation include Toyota Prius, Yaris, Land cruisers, Corolla, Auris, Lexus, and Camry.

Table 1: Company Overview

| Company Origin | Japan |

| Company Core Purpose | Automobile Manufacturing |

| Company Core Values | Innovation, Humility, Imagination, Respect, and Experimentation |

| Key Competitors | General Motors, BMW, Ford , Hyundai, Maruti Suzuki and Nissan. |

| Major Stakeholders | Toyota Motor Corp, Nippon Life Insurance Co., Toyota Industries Corp., and DENSO Corp. |

| Revenue | 29.38 trillion JPY |

| Website | https://www.toyota-global.com/ |

Source: (Toyota Website, 2018)

Description of the Problem Description

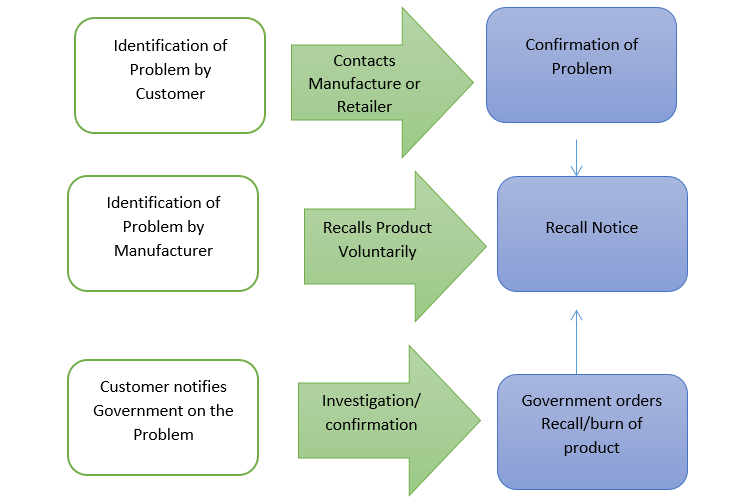

Toyota Motor Corporation made one of the largest recalls of vehicles in 2016 and 2018. In 2016, Toyota experienced one of the unintended acceleration crisis by recalling about 3.4 million cars reported to have flows involving curtain air bags and leaky fuel tanks. The Recall Process involved customers, governments, manufactures and the company as indicated in Appendix 1 (Whittaker 2018). The company was concerned that curtain air bags could crack and injure the occupants of these vehicles. The company recalled 2.87 million cars worldwide, including Corolla Compacts, and Prius hybrids on the basis of leaky fuel tanks.

Money Lost By Toyota As Result of Recall Process

Toyota Corporation lost a lot of money during the recall it is approximated that Toyota Company lost over $ 1.2 billion during the recall process in 2014. It was a very unfortunate incidence that made the company lose a lot of money, savings and anticipated profits. In fact, the management experienced unexpected losses during this period. No one thought that such a recall would recur after the previous recalls which had been resolved. The management thought that the recall issues would not recur within such a short period of time. Since 2001, the company had been experiencing recalls, with the works occurring between 2014 and 2017. By the end of 2017 financial year, Toyota Corporation recorded a loss of over 3 billion US dollars. The huge loss was as a result of the recalled vehicles which generated a lot of financial heat within the company. According to Whittaker, the Company had to meet the cost of repairing the affected vehicles without asking the customers for any compensation. In some cases, Toyota had to meet the transportation cost to the customers who were widespread in different countries. The management used a lot of money to try and correct the image that was at stake (Shirouzu 2015). The company notified the customers through emails that it would repair the vehicles and send them back. In this case, it had to work within the given deadline to ensure that the customers try to gain trust again to the company.

Reputation Damage

The reputation of the company was also at risk. Toyota has been one of the most trusted car dealers in the world. In fact, most of the people who bought the products did so because they wanted to belong to a certain class. Customers who use the vehicles from this company are believed to be wealthy belonging to the high class. However, the recall affected the existing customers as well as the potential customers. The customers felt that the company had failed them for manufacturing faulty products despite the trust they had in it for many years. In fact, the uproar in the social media shows that the world was so much disconnected because of the recalls. People felt that the company is not taking the right measures to prevent such mistakes. The fact there were recalls in the previous years indicated that the right decisions had not been taken to avoid recurrence. Thus, the customers were mad and some vowed never to try Toyota products again. Considering the number of people who had died in accidents resulting from the faulty vehicles, the reputation of the company was greatly affected negatively. The families who lost their loved ones cannot have them back even if the company repairs the remaining vehicles. They will live to suffer the loss of the mistakes that occurred in the eyes of professional. Nothing can replace the lives lost, and thus the dame will take ages to correct.

The dealers who were selling the Toyota products were not left behind. There are many investors who had stocked their shops with Toyota products as they were selling Gretel in their region. The 2014-2017 recall mad the customers to drop their trust in the company (Shepardson and Tajitsu 2016). They had a lot of dead stock as the customers could not purchase the products as they used to do. People feared the products as they were uncertain of the next products. Thus, the recall damaged the reputation of the company and it will take several years before it realizes full recovery.

The company expressed concern that the fuel emissions control canisters of these car models could crack and cause the fuel tanks to leak when they are at their full capacity and this could cause an accident. The company also recalled an additional 1.43 million vehicles, including Lexus CT compact and Prius hybrid vehicles on the account of leaky fuel tanks. The company indicated that Autoliv Inc- supplied it with partially inflated and cracked curtain air bags and these parts were to be repaired and fixed. On the overall, a total of 932,000 cars were involved in the two recalls. These recall led to increase in quality-related expenses incurred by Toyota Corporation during the year ending 2017.

In the most recent recall of vehicles with defaults, in 2017 Toyota Motor Corp recalled about 2.43 million cars globally. Of these recalled cars, the iconic Prius hybrid and its derivatives constituted 94%. The Auris compact hatchback hybrid version constituted the remaining 6% of the recalled cars as shown in Figure 1 below.

As revealed by Jean-Yves Jaut-Toyota Motor’s spokesperson, about 1.25 million of the recalled vehicles were in Japan; while 830,000 were in North America. Cars in China, Europe and other regions were also reportedly affected. For example, about 290,000 modes in Europe were affected of which 55,000 Auris and Prius models in the UK were affected by the recall. About 3,000 cars in China and other parts of the world were affected and recalled by Toyota Corporation. All the affected cars were manufacturing between 2008 and 2014 and had previously been recalled for related and other reasons in 2014 and 2015.

The software glitch prevented the failsafe mode of cars from engaging in the event of a fault in a hybrid system, and this could lead to stalling of the affected vehicles. At higher speed, breaking and power steering would remain operation. However, the stalling of the vehicle at these higher speed to potentially lead to a crash. As such, Toyota Corporation was concerned about the risk of crashing in the event this occurred while the car was at a higher speed. The company reported that the recall was aimed at addressing situations which hard acceleration combined with the failure of a component could result in the car losing power instead of it entering the failsafe driving mode (Kelly, 2012). Reports concerning the issue of software glitch had been noted in Japan though no crashes had been reported that were pinned to the software glitch. The company could not comment on similar incidents that occurred outside Japan claiming that it could not be certain about actual cases.

Table 2: Timeline of Recalling

| Date | Happenings |

| June, 2014 | After complaints from customers, the National Highway Traffic Safety Administration (NHTSA) started a formal investigation on the faulty airbags. |

| February 2015 | NHTSA reports that there was a problem with Toyota products, and orders the company to pay consumers $14,000 every day for the time they have stayed with the faulty product. |

| May 2015 | Toyota acknowledged that the 6 deaths that had been reported resulted from manufacturing problems. It agreed to compensate the affected people and victims in agreement with NHTSA demands. |

| June 2016 | The Federal government Auto Safety Regulators conducted a research that concluded that one out of ten airbags raptured and caused accidents. |

| May 2017 | The Toyota Company pleads guilty of the deaths that had occurred because of failures on its side. |

| May 2017 | The automobile company issues a recall notice to all customers who had complaints. |

| June 2017 | The Company compensates the customers and promises to complete the compensation process the soonest possible. |

Toyota Corporation is a giant organization that operates in twenty seven countries and has more than one hundred and seventy dealer networks all over the world. In this case, anything that happens to the company is easily known to people. The advancement in technology has enabled people to share information through social networking sites. Whenever an individual shares a certain problems, the entire world leans about it in hours. This is the main problem that caused a huge crisis in Toyota Corporation. After some people shared a busted airbag, the image spread to all parts of the world and within a few days, everyone with Toyota products was complaining. Immediately the Toyota Recall Crisis stated, the social media was on it. Everyone was discussing how Toyota has failed. People attributed all accidents that they had to the failure of the manufacture. This made it hard for the manufacturer to deny because people from all parts of the world were against the company. Thus, Toyota had to own up and come up with a strategy that would save the situation.

Description of the Approach Used

Toyota experienced negative image and public relations as a result of the recalls. It was necessary for the leadership to take an action that would change the public attitude towards the company. The Image Repair Theory as formulated by Boneit & Pang point out that an event or process that destroys the image of an organization has two elements: accused takes responsibility, and an offensive action has taken place. This means that the organization has to do everything possible to reverse the negative public attitude that has been caused by the occurrence that destroyed the image (Shepardson and Tajitsu 2016). This image fits in the case of Toyota because the Company suffered recalls which negatively affected its reputation. In fact, the high number of recalls is attributed to the social media contribution. People shared a lot of negative information about the products, making even those who had not realized the problem to return their products. After the denial, there was a need to use this theory to correct the threat.

In enhancing the approaches to be used in recall process Toyota Company had to develop the suitable means of communication. Over hundred Toyota dealers worldwide were the acted as the main source of information since they had direct contact with the customers. The dealers obtained the information from customers and conveyed it to the Toyota Company, then the Company gave feedback to customers through dealers. The process of recalling was made effective by the fact that dealers were willing to offer support to the company Ghannam. The support by the dealers was the main reason why the Toyota Company succeeded in the recall process as it was noted by Benoit. According to Benoit the customers who had complains about their cars were required to return them to the dealers who sold to them. The customers were either refunded certain amount of money or were to wait for certain duration of time as their cars were being repaired. There were no much complaints from customers after the hybrid vehicles were repaired and returned to customers (Brauer 2014). This indicates that the issue was fully solved and customers were satisfied.

The Image Repair Theory gives the organization a platform to adjust the situation so that it can reduce the threat brought about by the negative image. The theory advocated for an effective commination that will deal with the communication crisis at hand. There is need to mitigate the threat and prevent further damage that might occur. Categories of the Image Repair Theory bare indicated in the Figure below.

Figure 2: Image Repair Theory Model

Toyota went through the four phases in the Image Repair Theory. There was need to tackle the fourth action of corrective action so that the damage could be reduced. Considering the fact that there were more than 10 Facebook pages which were against Toyota Products as a result of the injuries they had caused, Toyota management decided to use Power of Social networking Site as advocated by Ghannam. This method was successful and helped the Company to gain its reputations again.

SNS Strategy

Toyota Corporation come up with an urgent “Online Newsroom” that was to be guided by the “social media strategy team”. The team was given the responsibility of ensuring that they check the news that the company releases either form the dealers, customer service and public relations department. The organization was active in Facebook, Twitter, and You Tube. It also opened a Toyota Pressroom that could release the right information to the people to reduce the confusion in the public domain. The SNS team found out that there were ten Anti-Toyota Facebook Pages that were active. In this case, the team decided to add the number of Facebook Followers in the page so that more people could acquire the right information. Therefore, the team increased the number of followers on its page with 10% every month in the year 2017.

When a company taps on SNS, it gets an opportunity to get customers’ feeling before the world learns about some negative issues. Customers were allowed to air their views on the online platform. The social media strategy team was active and answered all the questions that the customers asked. They clarified confusing information that was in the public domain. According to MH Group, the automotive industry has not embraced the use of social media when purchasing products like it happens in other industries. However, as Chen, Fay, & Wang note, the social media platforms play a vital role in the final decisions. In this case, people started changing their attitudes towards the company. The number of people in the anti-Toyota groups was less than 2% of those in the official Toyota Page Ghannam. In this case, therefore, the company managed to spread the good news of the company and surpassed those who were spreading negative information. PRIUSchat was one of the sites that had greatly damaged the Toyota Image, but with time the followers started questioning the authenticity and purpose of the groups (http://priuschat.com/). The social mead team joined such groups and distorted the information given, making people to doubt the sites and started to quit. Unfortunately, the solution of the SNS could not be long-lived because there were other issues that needed to be handled.

Suitable Decision Making

Toyota Company made the most appropriate decision by recalling the defective Hybrid Vehicles. According to Brauer, the Toyota Company could have suffered great loss if it management never rushed to make the decision of recall the defective vehicles. Considering the factor that Toyota Company is well established entity in terms of production and marketing strategy it have lowered its reputation. Although recalling of the vehicle was very expensive process which led to decline in profit margin, it enabled the Toyota Company to dominate the market over other companies. Dominating market has led to rapid growth within Toyota Company after recall period.

Appropriate Problem Solving Techniques

The great loss experienced by the Toyota Company and the investors was wrong method of recall of the Hybrid Vehicle which took place from June 2014- June 2017. Their well-documented analysis, Kehr & Proctor postulate that the process of recalling was not the most appropriate method to deal with the defective Hybrid Vehicles. According to them, the recalling process was very expensive hence bring unnecessary losses to the company. For example recalling about 830000 cars from North America was an expensive move, instead the company should have considered repairing the cars within North America. The Toyota Company could have opened a workshop where all defective cars in North America could have been repaired. This formula could have been duplicated in other countries in Europe. This method was the most appropriate since it could have enabled the company to save a lot of it resources and minimizes the losses which occurred.

Critical Issues Associated with Toyota’s Crisis

Though Toyota Corporation linked the recalling of the vehicles to software failure, the issues are largely based on undressed issues namely, the company’s failure to respond appropriately to its aggressive growth; increasing central management; increasing complexity of the vehicle compounded by accelerated design cycles; increased numbers of models; and standardization of bad parts; increasing overreliance on computer aided design; increasing complexity of its supply chain; and slow response to customer complaints. Those were the main reasons why the company had to recall the hybrid vehicles.

Suggestion on Improvement

Toyota requires understanding the root causes of the problems so that it can be able to resolve each problem independently and avoid recurrence of the same mistakes. Thus, this section describes the root causes of the problems and highlights suggestions to improve the situation.

Recent Aggressive Growth

One of the possible causes of repeated recalls of Toyota’s hybrid vehicles is the inability to keep pace with the fast and aggressive growth and increase in sales. This aggressive growth was spurred by 2005 aggressive growth plan launched by Hiroshi Okuda the then president of Toyota Motors Corporation. This plan saw Toyota Corporation increase its market share to 9.7% and achieve its 15% goal of increasing vehicle production up from 5 million vehicles to 8 million vehicles. As theorized by Ede, Toyota found it difficult to use its organizational capacity and Toyota Way Strategy within its production facilities in order to match the increasing business globalization trends and vehicle complexity. Kehr and Proctor also agree that the Toyota recorded rapid growth in sales and this proved difficult for the company to manage it efficiently. It is also believed that Toyota largely focused on growth and this skewed its traditional priorities of Toyota Way Guiding Principles. The market share also grew aggressively at the expense of Toyota’s short-term gains and brand reputation. Philosophically, Toyota’ Principle 1 proposes that purpose should supersede market share expansion and short-term financial gains. The company’s focus on expanding market share rather than on long-standing reputation of durability and reliability was against its TPS and Toyota Way philosophy.

Increasing Vehicle Complexity, Accelerated Design Cycles, Increased Numbers of Models, and Standardization of Bad Parts

Another possible root of cause of quality problem in Toyota’s hybrid cars as cited by industry experts is the increasing growing complexity of the hybrid vehicles. It is argued that strict government safety, fuel regulations and emissions compounded with rising demand by consumers for green and luxury automobiles mount pressure of Toyota Motors and other automobile makers to design vehicles encompassing multiple electronic control modules and multiple lines of computer codes. This creates the demand on the part of Toyota to validate and verify the performance of these electronic control modules using extensive engineering development testing. As indicated by Montgomery, these types of complex components and modules could naturally experience electro-mechanical issues as a result of rapidly changing technology without necessarily being contributed by the company’s emphasis on the growing market share globally. However, Toyota Motors’ decision to increase product offering to include hybrid vehicles like Prius and Auris models could have compounded the challenge. The recurrence of issues that warranted repeated recall of the same vehicles Prius and Auris suggest that Toyota may not be having enough engineers experienced with these complex mechanical systems in order to ensure the Toyota’s hybrid models were adequately tested and properly designed. It is argued that increasing complexity of vehicles produced by Toyota compounded by increased model lines and accelerated design cycles strained development systems and product pushed personnel resources to its limit, and ultimately creating perfect conditions for failure in quality as it was evident in the hybrid models: Prius and Auris models. Indeed, the confluence of accelerated design cycles, increased complexity and number of model lines is reflected in the Toyota’s complex cars recalled during the 2014-2015 and 2016-2017 recall. For example, as noted herein the iconic Prius hybrid and its derivatives constituted 94% with the Auris compact hatchback hybrid version accounting for the rest of the recalled vehicles.

In keeping with the requirements of principle 6, Toyota Company increased standardization across its vehicle model lines. Principle 6 identifies standardized tasks as the foundation for continuous empowerment and improvement. The argument is that through standardization, a company can increase the scale of improvements. The standardization principle also posits that stable and repeatable methods should be used everywhere to maintain regular timing and predictability for pull and flow. On the contrary, standardization is also thought to increase the scale of defects. In line with this perspective, because Toyota standardizes components across multiple vehicles, a problem in a single bad component as it was the case with the software used in the hybrid vehicles led to the recalling of other models because other types of vehicles were equally affected. This multiplication effect of standardization is evident in Toyota’s recall of different models in 2014 through to 2017.

In light of increasing number of Toyota’s model lines, expedited design, complex systems, and standardizing multiplying effect of bad parts, Toyota Corporation violated the Toyota Way’s Principle 8, which emphasizes the use of only technology that is reliable and thoroughly tested. The crucible of principle 8 is for Toyota Company to reject technologies that are considered as conflicting culture or those that can potentially disrupt stability, predictability and reliability. This demonstrated that by producing vehicles with unreliable and faulty software and increasing vehicle expediting designs, model lines, and complexity, Toyota demonstrated the failure to do a thorough testing of the reliability of products and parts before standardization, and this resulted in the multiplication of negative impacts across its hybrid vehicle models.

Increased overreliance of Computed Aided Design (CAD)

Since 1990s, Toyota has been using high-tech Computer-Aided Design (CAD) tools to radically streamline the development process of its vehicles. Toyota use Computer Aided 3-Dimensional Interactive Application to cut development time for new vehicles to a shorter time from initial 3-4 years. The company also uses CAD tools to cut on the number of prototypes built per vehicle from original 60 to fewer than 20. The company executives analyzed Toyota’s design processes and found that despite using CAD software, Toyota still made mistakes. It is argued that the mistakes were committed because of Toyota’s overreliance on CAD what Schrage describes a “perils of pathological prototyping” which tend to grotesquely amplify the model’s technical flaws.

Slow response to Customer Complaints by Toyota Motors Corporation

As demonstrated in the 2014-2017 recall of the Auris and Prius hybrid car models manufactured between 2008 and 2014, Toyota Motor Corporation had demonstrated that was delinquent in monitoring and responding to customer complaints. As suggested by Kehr and Proctor, from a technical perspective, Toyota may have shown determination to speedily respond to recall issues by managing logistics and identifying possible solution to the software hitches that hit the hybrid car models; however, minimum communication with consumers may have contributed to slow response to issues. There are three possible factors that may have contributed to slow response by Toyota towards issues that warranted led to the recall of the hybrid vehicles: complex bureaucracy in Japan; failure to taking seriously the subjective concerns by Toyota engineers; and overly controlled public relations by the Toyota’s management in Japan and its irresponsiveness. As suggested by Liker, rapid response to consumers’ response is key to Toyota’s continuous improvement principle 14 and relentless reflection. As further indicated by Liker reflection helps organization identify the project’s shortcomings. Wu also suggests that customer relationships can be addressed by taking a keen interest in monitoring vehicle warranty claims by customers. Wu further hinted that it could have been possible for Toyota to mitigate recall crisis associated damages by embracing the implementation of early warranty detection algorithms informed by the analysis of vehicle warranty data. Statistical methods could also be useful in detecting abnormal change trends and points in warranty data facilitating the management to early detect indications of unexpected reliability and quality problems.

Other Suitable Approaches

Toyota Corporation responded in different ways to the recall of the hybrid vehicles crisis: shifting emphasis from computer aided design and virtual prototyping to prototyping; and changing media relations.

Shifting Emphasis from Computer Aided Design and Virtual Prototyping to Prototyping

Toyota responded to the criticism of overlying on the CAD software by relying less on computer-aided design and virtual prototyping when developing new products. Toyota also reverted to old system of focusing on building sheet metal prototypes to identify problems before launching a new model of car. The company went back to the physical product and reliance on the human senses to think about the car and quantify it. This directive added about 6 months to the project. Now, Toyota tasked its engineers with verifying the product and the robustness of design changes after and during the development process of the product. It ensures the virtual prototyping and traditional physical prototyping was balanced.

Suitable/Best DMPS Techniques

Re-structuring of the TPS House

Toyota Company acknowledged that TPS house failed it. In response Toyota Motors adopted modifications to respond to changing conditions in the global market. In the spirit of improving continuously on its operations, I suggest that TPS House should be enhanced. There are both external and internal people at the heart of Toyota’s TPS House upon which the company’s decisions rest. Most recall problems experienced by Toyota may be linked to people. Again, metaphorically, the violation of TPS principle may have contributed to the breaking up of Toyota Motor’s roof. Therefore, a structural change would have been done by Toyota’s management to clearly highlight the role and importance of people in TPS House. Toyota could have ensure the heart of TPS accounted for fundamental different population of individuals whom TPS relies upon: employees, suppliers, and customers. It was also necessary for Toyota to add structural support to people that constitute these three groupings to help facilitate the success of continuous improvement. As illustrated in figure 2, people are pillars that can potentially improve the TPS House Model.

Customers

As earlier identified, the Toyota Way principle requires Toyota to have a stronger commitment to the society and customers. Thus, customers should be Toyota’s pillar of the TPS House paradigm the principle of self-reflection should also be extended to Toyota’s customers. A customer pillar is proposed in figure 1 that recognizes why it is important to capture and adapt customers’ experiences and perceptions as early as possible. It may be a challenge for Toyota to ingest customer perceptions given that customers tend to differ in their thinking from employee production operators. Customer feedback can be influence by misleading conclusions, media, or emotion, often the company should take keen interest in perception is it matters than reality. Therefore, Toyota should have in place a mechanism that facilitates relationships with its customers by offering rapid feedback to the management in order to help it identify possible real quality issues in a timely manner.

Are you interested in our Critical Evaluation of Toyota Corporation: Recall of Hybrid Vehicles 2014-2015 and 2016-2017? Click the button and download pdf sample to read full version of this paper.